By Giovanni Roverso

Dave Brasher, co-owner and co-founder of High Energy Metals or HEMi, offered a presentation at the Peninsula College Little Theater on Jan. 22. about the Sequim-based company which specializes in explosion welding. This welding technique produces strong bonds between different metals which can not be welded together effectively by other more conventional methods.

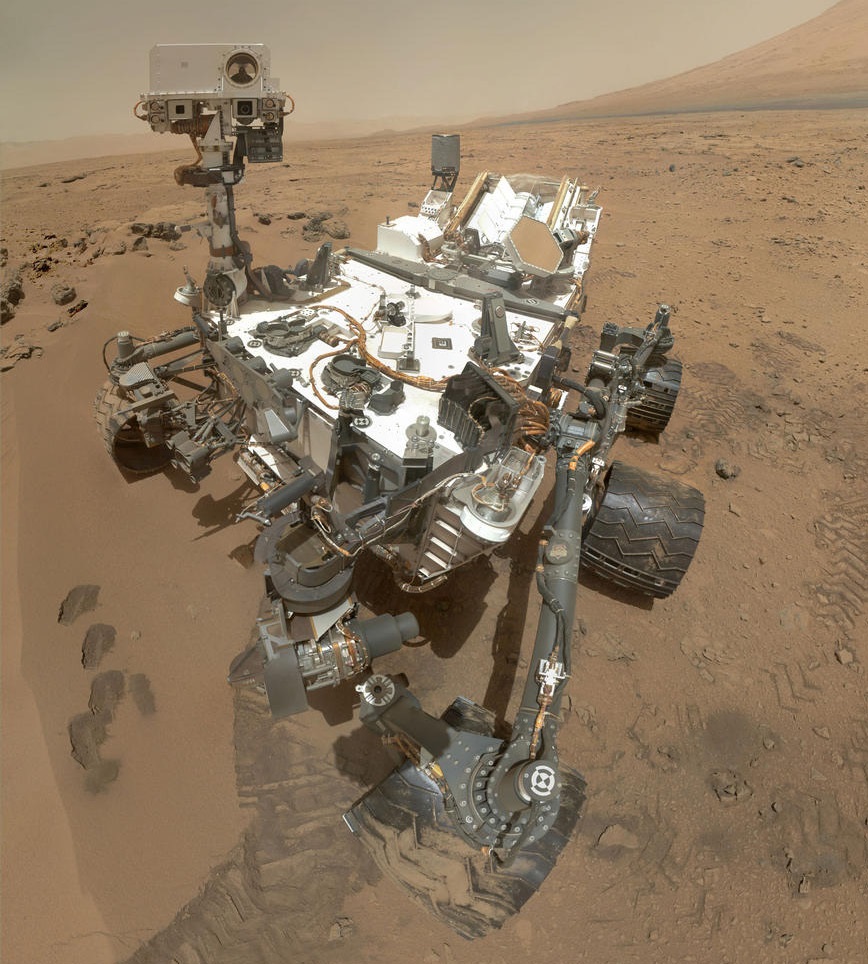

HEMi has worked on high-profile projects such as components for the NASA Curiosity Mars Rover nuclear reactor as well as the internal shielding plates for the French ITER fusion reactor prototype.

Brasher touted explosion welding’s many advantages over alternative bonding methods. One advantage is that the original strengths of explosive-bonded metals are maintained thanks to the nature of the bonding reaction which Brasher called a cold welding process, which he said creates a true metallurgical joint.

Brasher said that the technique’s main disadvantage is that it is restricted in form, usually flat plates and circular geometries which are then machined into desired shapes.

HEMi came about in 1997 after Northwest Technical Industries, a company which was founded 1983, was sold to Pacific Aerospace & Electronics. The original company owner, Alan Hare, who Brasher said was both a boss and mentor to him, brought his understanding of the technology with him from his years at DuPont in the 1970s and followed NTI after the buy-out. Brasher, the vice president, and Don Butler, senior projects engineer, then started HEMi.

Since ’97 its team of two employees has slowly grown in size to twelve and is now in search of another. A paid internship will be offered in spring to continue throughout the summer. Prospective interns will require machining skills, including an understanding of computer numerical control (CNC).

Brasher can be reached at info@highenergymetals.com.